分(fèn)切機系列(liè)當前(qián)位置(zhì):首頁 > 分切(qiē)機系列

clfq-qw型全自(zì)動電腦(nǎo)高速複卷分切機(jī)

發布日期:[2021-03-05] 點(diǎn)擊率:

主(zhǔ)要技術參(cān)數(shù):main technical parameters

機型 model | clfq-qw1300 | clfq-qw1600 |

最大原(yuán)料寬度(dù)max. width of raw material | 1300mm | 1600mm |

最大(dà)放(fàng)卷直徑max.parent web diameter | Φ1500mm | Φ1500mm |

最(zuì)大收(shōu)卷直(zhí)徑max.rewinding diameter | Φ1000mm | Φ1000mm |

最高機(jī)械速度 max.machine speed | 10-400m/min | 10-400m/min |

總(zǒng)功率(lǜ) total power | 25kw | 29kw |

重(zhòng)量 machine weight | 4300kg | 4800kg |

外形尺寸(cùn) overall dimensions | 3200×2900×2000mm | 3200×3200×2000mm |

最小分切寬度(dù) min.slitting width | 20mm | 20mm |

可根據産品要(yào)求 特殊訂制設(shè)備。

can be made according to the product requires special equipment.

産品說明

适(shì)用範圍

本機适(shì)用于各種超(chāo)大(dà)型卷材的(de)分切,如30g/m2-400g/m2牛皮紙、白卡紙、淋膜紙(zhǐ)、鋁箔(bó)、pvc塑料、錫(xī)紙(zhǐ)等卷(juàn)材的分切(qiē)、複卷(juàn)等。

性(xìng)能及特點(diǎn)

1. 該機采(cǎi)用(yòng)異步(bù)伺服(fú)電機(矢量(liàng)電機)控制、自動(dòng)錐度(dù)張力,中心(xīn)卷取方式。主機采用變(biàn)頻(pín)調速(sù),保持加速(sù)中平(píng)衡(héng)運轉(zhuǎn)。

2. 自(zì)動計(jì)米、報(bào)警功能。收卷采(cǎi)用a、b氣(qì)脹軸(zhóu)結構,卸裝操作方便(biàn)。

3. 放卷采用(yòng)光電自動(dòng)糾偏(piān)修正系(xì)統,使不(bú)規則材料(liào)能正常分切。

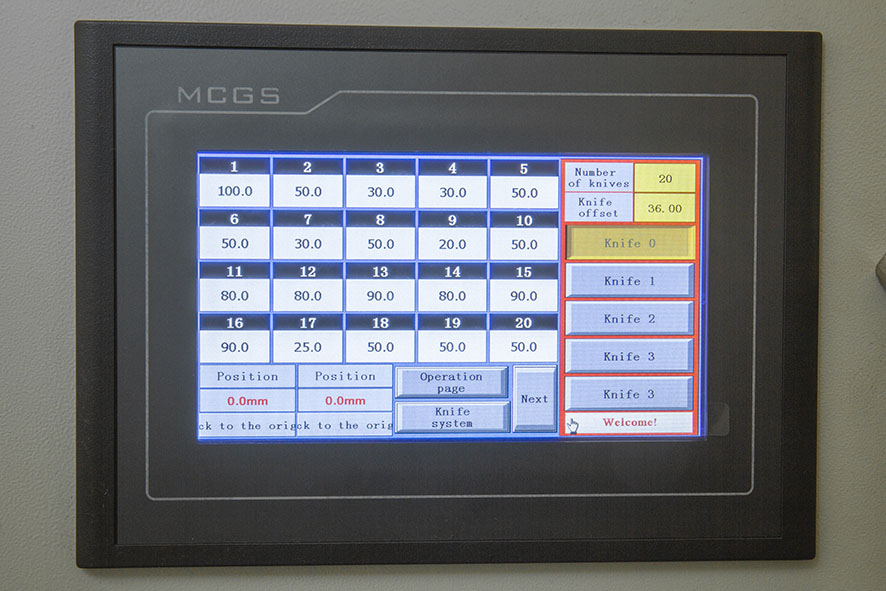

4. 自(zì)動調(diào)刀系(xì)統(輸入你需要(yào)的(de)分切規(guī)格一次排(pái)好刀(dāo)具),圓刀(dāo)縱(zòng)切廢邊自動(dòng)排(pái)放裝(zhuāng)置。

5. 油壓式自動(dòng)上(shàng)下料,無(wú)軸裝(zhuāng)卷。

6.導軌式(shì)自動(dòng)下料裝(zhuāng)置(zhì)。

product manual

scope of application

this machine is suitable for the slitting and rewinding of various super large coils, such as 30g/m2-400g/m2 kraft paper, white cardboard, coated paper, aluminum foil, pvc plastic, tin foil and other coils.

performance and characteristics

1. the machine adopts asynchronous servo motor (vector motor) control, automatic taper tension, and center winding mode. the host adopts frequency conversion speed regulation to maintain a balanced operation during acceleration.

2. automatic meter counting and alarm function. the rewinding adopts a and b inflatable shaft structure, which is easy to unload and operate.

3. the unwinding adopts the photoelectric automatic correction system to make the irregular materials can be slit normally.

4. automatic tool adjustment system (input the slitting specifications you need to arrange the tools at one time), and the automatic discharge device for round knife longitudinal cutting waste.

5. hydraulic automatic loading and unloading, without shaft loading.

6. guide rail type automatic unloading device.

聯系(xì)我們(men)

了解(jiě)更多我們(men)詳細信息(xī),請緻電(diàn)

13868813586

13967793790

手 機:13868813586/13967793790

電(diàn) 話:(86)577-65987363

地 址:浙(zhè)江省瑞安市上望街(jiē)路頭(tóu)工業(yè)區(qū)10-1号(hào)

e-mail:1480550208@qq.com

掃一掃關注我們(men)

copyright © 2018 昌力機(jī)械设(shè)备有限公(gōng)司. all rights reserved. 浙icp備18010182号-1 複卷(juàn)機廠(chǎng)家, 分條機(jī)廠家主營: 全自動分(fèn)切機(jī) 紙張(zhāng)分切機 高速分(fèn)切機(jī) 薄膜分切機